This article understands the development of diaper core structure.

At present, the change of China's population structure has brought about great development potential for China's diaper market. The implementation of the two-child policy and the change of parenting concepts have greatly stimulated the development of the infant diaper market and into the rapid growth period.

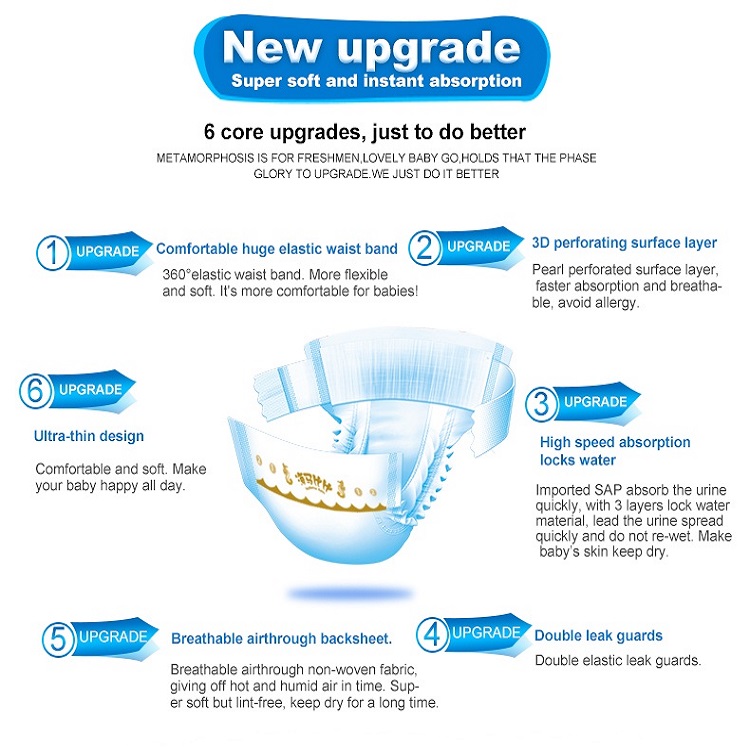

The diapers on the market are all kinds of products, but they are mainly composed of skin-friendly surface layer, diversion layer, absorption core, back layer of these four parts.

Among them, the absorption core is the most important structural component in diapers. As the main absorption layer, it is required to absorb urine quickly and spread urine to the whole absorption core by the use of diversion and core absorption. Then, the absorbent resin (SAP) can quickly absorb and lock urine, and make it non-reverse osmosis.

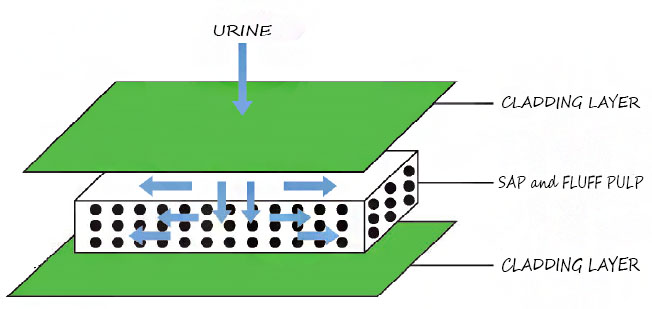

The cladding layer is made of tissue paper or non-woven materials or multi-layer composite materials. The upper cladding layer usually has the functions of diversion and ventilation, while the lower cladding layer usually has the functions of anti-seepage and barrier.

Villus pulp ( fluff pulp) can fix SAP to a certain extent, prevent SAP from moving and piling up, and keep the surface of diapers smooth and soft.

In addition, the core-suction effect of fluff pulp can solve the problem of gel blockage after SAP suction, weaken the phenomenon that diapers are prone to glop after SAP suction, and improve the feeling of wearing comfort.

But, in this kind of diapers, the wearer should avoid large mobile slip or flip in SAP, and caused the uneven distribution, SAP distribution areas more quickly and expansion and hinder the spread of urine, eventually lead to faults, tuo, influence of diapers fluid absorption for many times, more severe cases can cause surface film tear, urine leakage, stimulate the wearer of the skin.

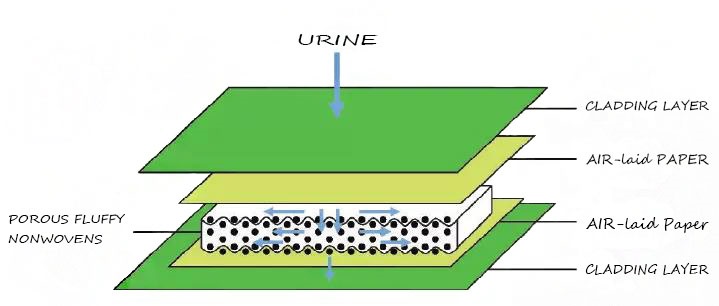

As diaper products become thinner and thinner, and people have higher and higher requirements on absorbent performance, new composite absorbent cores are emerging.

It is usually coated with dust-free paper and porous fluffy nonwovens, then spread SAP between porous fluffy nonwovens, and then use hot melt glue to bond each layer.

Ultra-thin composite absorbent cores generally have the defect that the absorbent speed is faster at the first time and then decreases seriously, while the traditional villous slurry absorbent core has a more balanced absorbent speed.

With complex structure and many layers, it has lower production speed and higher production cost compared with the traditional villous pulp absorption core.

With the continuous improvement of people's requirements for lightweight, breathable, liquid absorbent, hygienic and non-stimulating diaper products, the diaper absorption core will develop towards the direction of diversified and comprehensive functions, and the structure of the absorption core will be continuously improved.

Among them, the research on the structure of composite absorption core will bring new breakthroughs to the field of sanitary products, which is conducive to grasping the needs of consumers, developing better new products, giving play to the potential of China's diaper market, improving market penetration and expanding market share.

Categories

Recent Posts

Tags